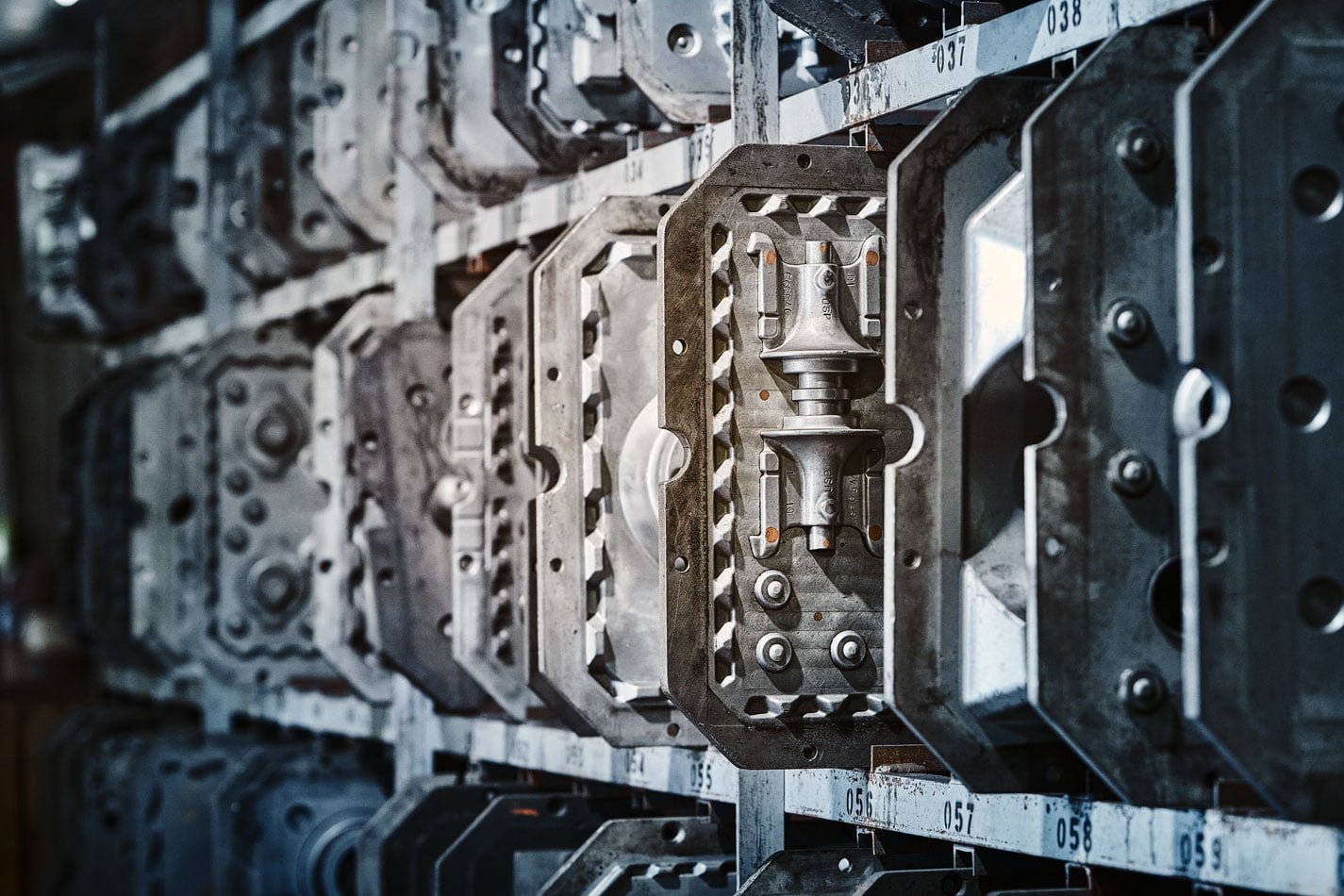

Pattern Design Optimization

Pattern Design and Optimization comes in after customers provide the casting specifications. We require a model or drawing of the current revision level as well as a casting number and/or a part number. Our experts examine the model or drawing to make sure the casting is optimized for production. If we find any parts of the specifications that aren’t optimized, we reach out to the customer to redesign those portions.

The most common optimization comes in the pattern’s draft. To create less scrap and optimize production, we analyze customer patterns and make recommendations to improve, which includes redesigning areas with 90-degree angles.

Patterns are produced utilizing both CNC machining processes and more traditional methods. We use licensed software for all pattern updates. This includes CAD Solidworks, Autocad, Pro-E and SurfCam as well as Finite Solutions Solidification Analysis through Solid Cast and Opti Cast.

All patterns are subjected to an itemized list of testing and inspection requirements.

Testing and Inspection Requirements

Visual Inspection

Hardness

Saw-Cut

Dimensional Layout

Chemical Certification

.

Physical Certification

Metallographic Analysis

Letter of Compliance

Part Retention

Gauging

.

Ready to Get Started?

Let’s connect and talk about your needs and how we can work together to get the most out of our partnership.